Expert Services for

Process Industries

From strategic consulting and benefit studies to hands-on digital twin building and full-scale digital transformation — we deliver measurable results.

Process & Equipment Optimisation

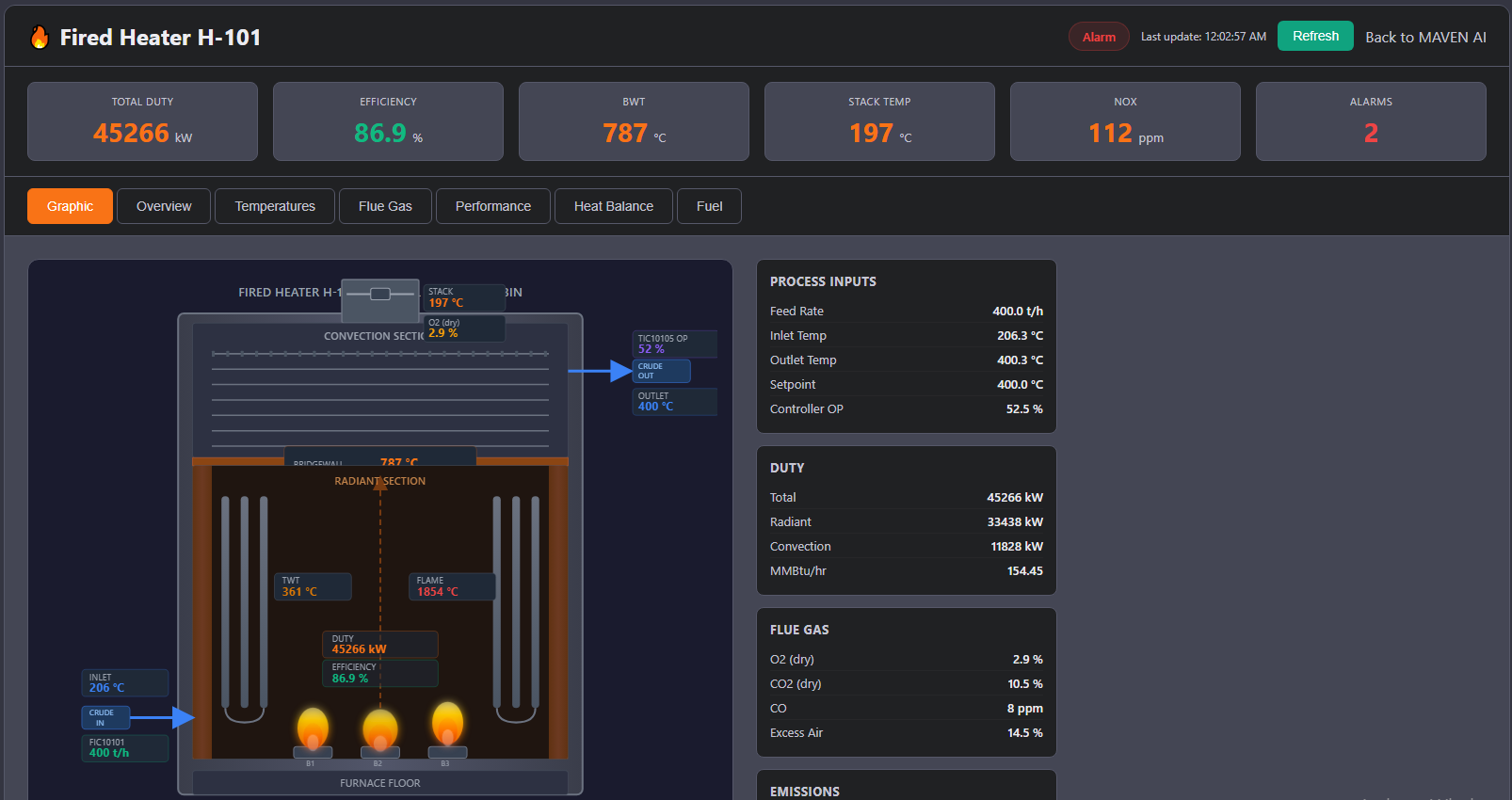

Our experienced process engineers optimise your operations for maximum efficiency, reduced emissions, and improved equipment reliability — from fired heaters and distillation columns to complete unit-wide optimisation.

- Fired heater optimisation for fuel efficiency and emission reduction

- Flare gas recovery and emissions minimisation strategies

- Distillation column optimisation and energy integration

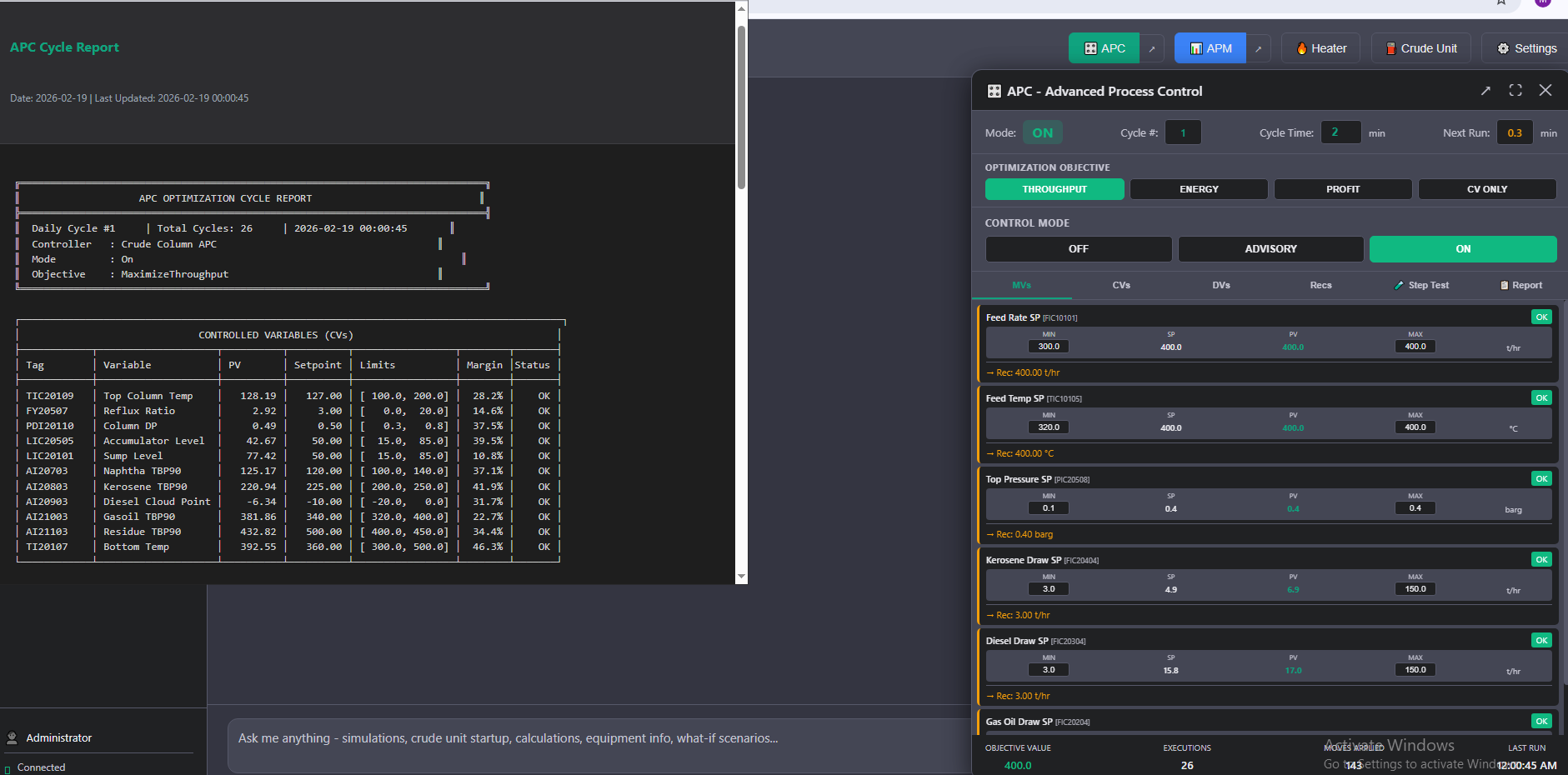

- APC/MPC strategy development and benefit studies with quantified ROI

- Process control assessment, gap analysis, and controller tuning

- Knowledge transfer and operator training

Custom Process Simulation Models

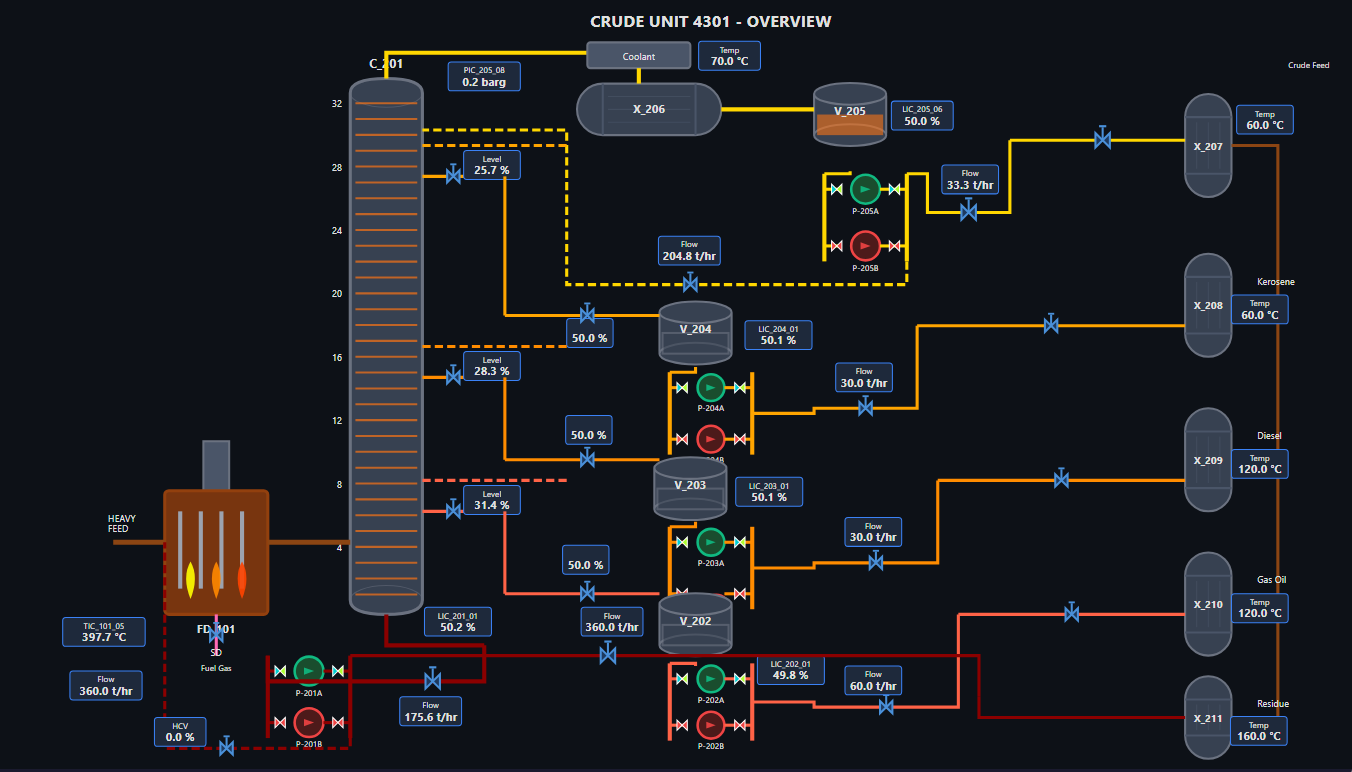

We build high-fidelity digital twins of your process units using rigorous thermodynamic simulation, connected to real-time plant data for continuous validation and optimisation.

- First-principles steady-state and dynamic simulation using industry-leading tools

- Real-time OPC data integration for live validation

- What-if scenario analysis for process optimisation

- Operator training simulators (OTS)

- Interactive P&ID visualisation with live data

- Custom equipment models for unique unit operations

Modernise Your Operations

We help process facilities transition from legacy systems to modern, connected operations — integrating SCADA, DCS, historians, and cloud analytics into a cohesive digital platform.

- Legacy system assessment and modernisation planning

- SCADA/DCS integration and data unification

- Industry 4.0 roadmap development

- OPC gateway and protocol bridge implementation

- Real-time dashboards and KPI monitoring

- AI and machine learning integration strategy

How We Deliver Results

A proven methodology refined over 23+ years in process industries.

1. Assess

Understand your current operations, identify opportunities, and quantify potential benefits.

2. Design

Develop a tailored solution architecture and implementation roadmap aligned with your goals.

3. Implement

Build, configure, and deploy solutions with rigorous testing and commissioning support.

4. Sustain

Ongoing support, performance monitoring, and continuous improvement to maximise long-term value.