Digital Twin Platform

Create a living digital replica of your process plant — combining real-time data, rigorous thermodynamic simulation, and interactive what-if scenario analysis to optimise operations and de-risk decisions.

Comprehensive Digital Twin Capabilities

Everything you need to model, simulate, and monitor your process plant in real time.

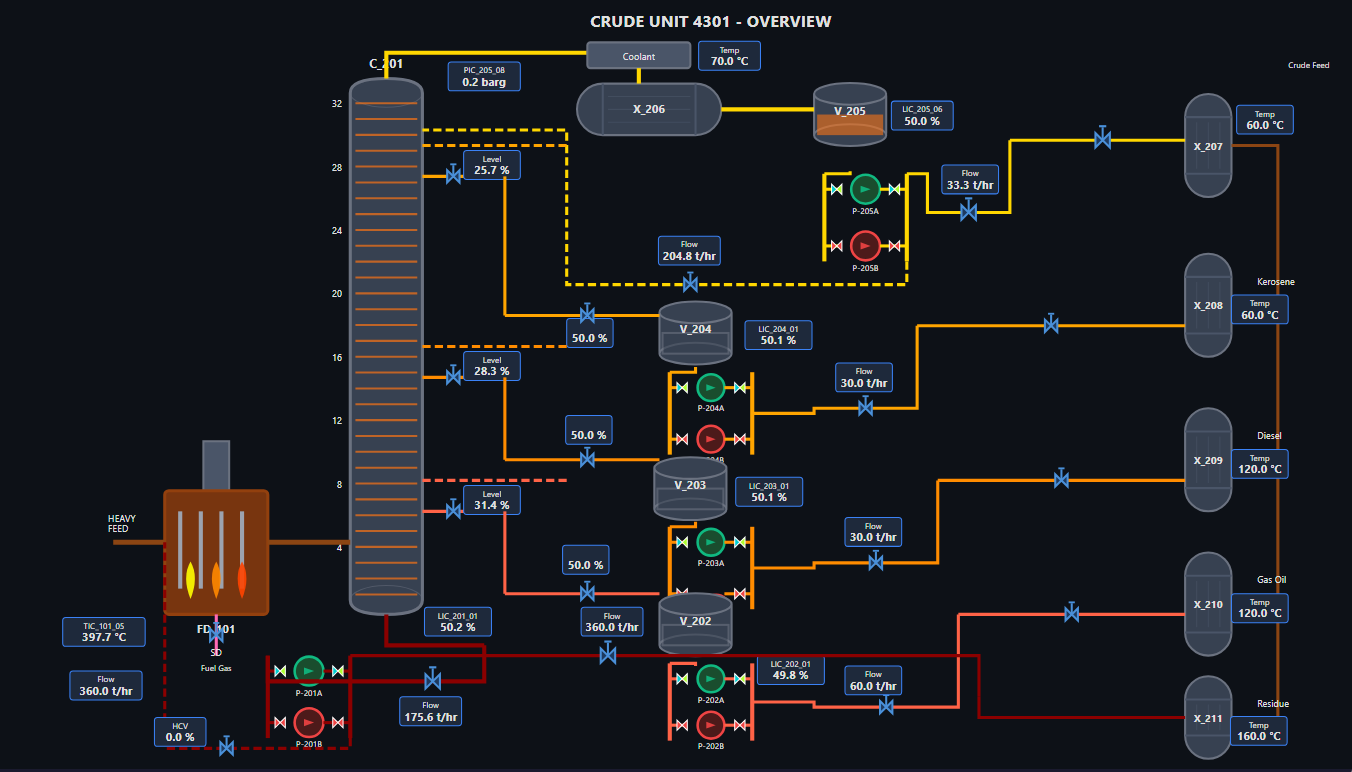

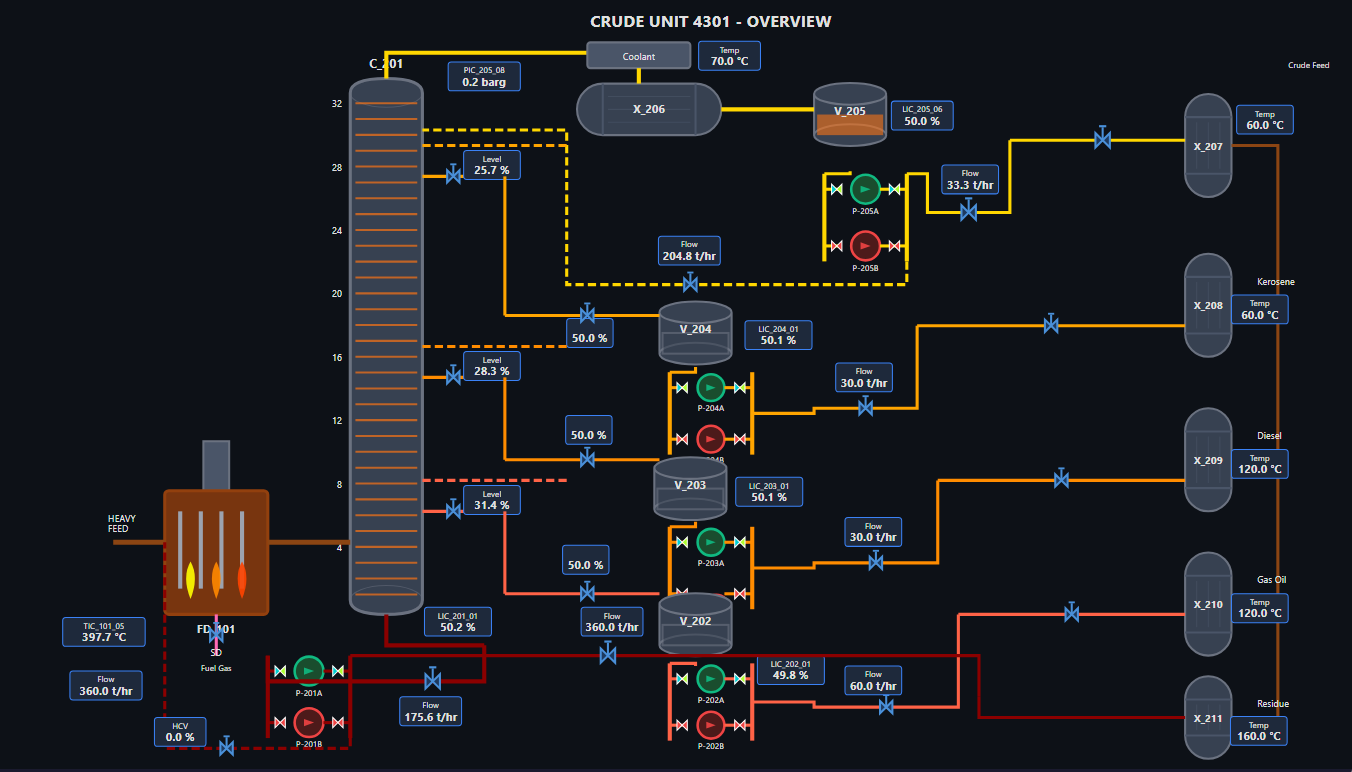

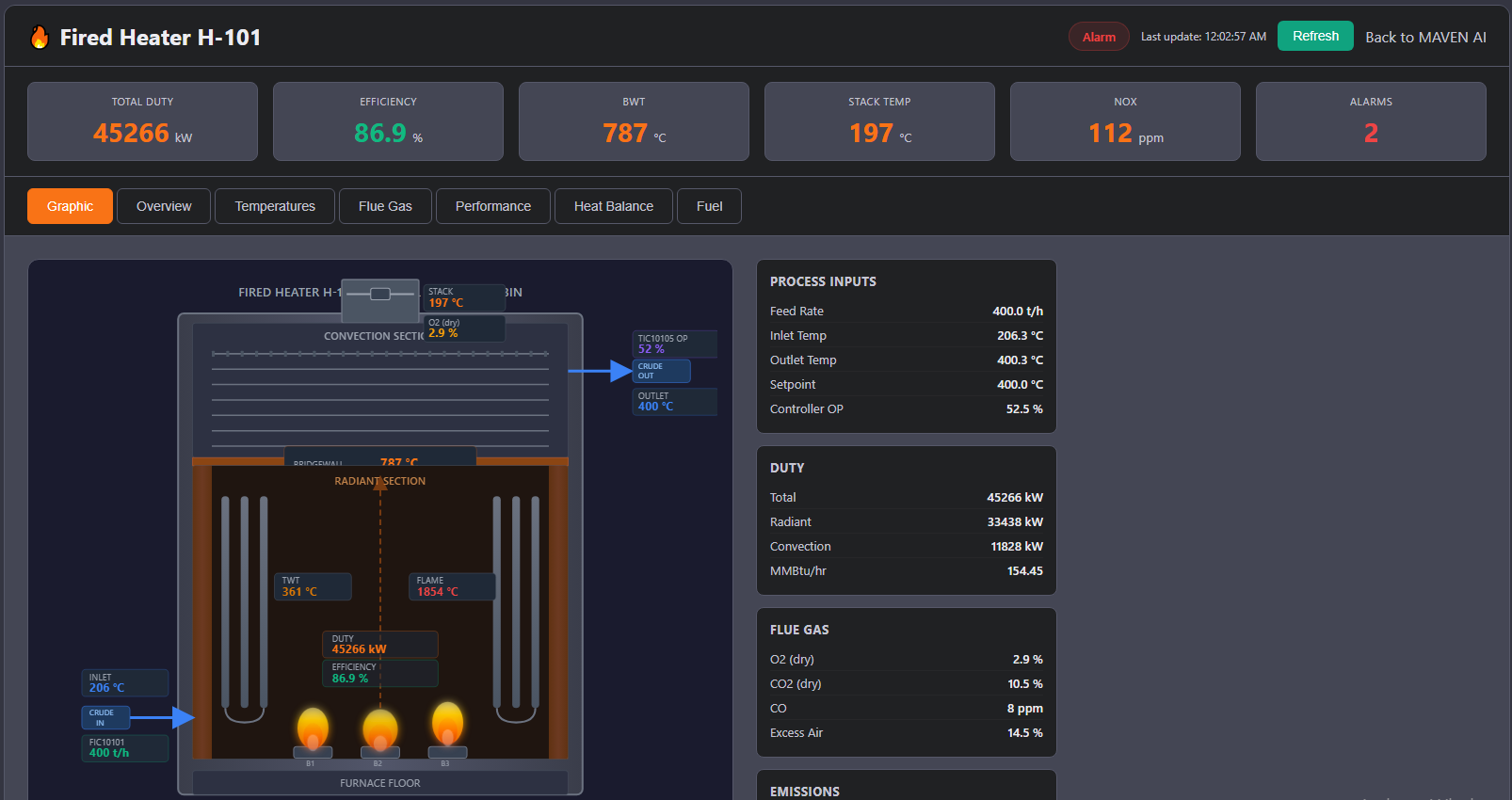

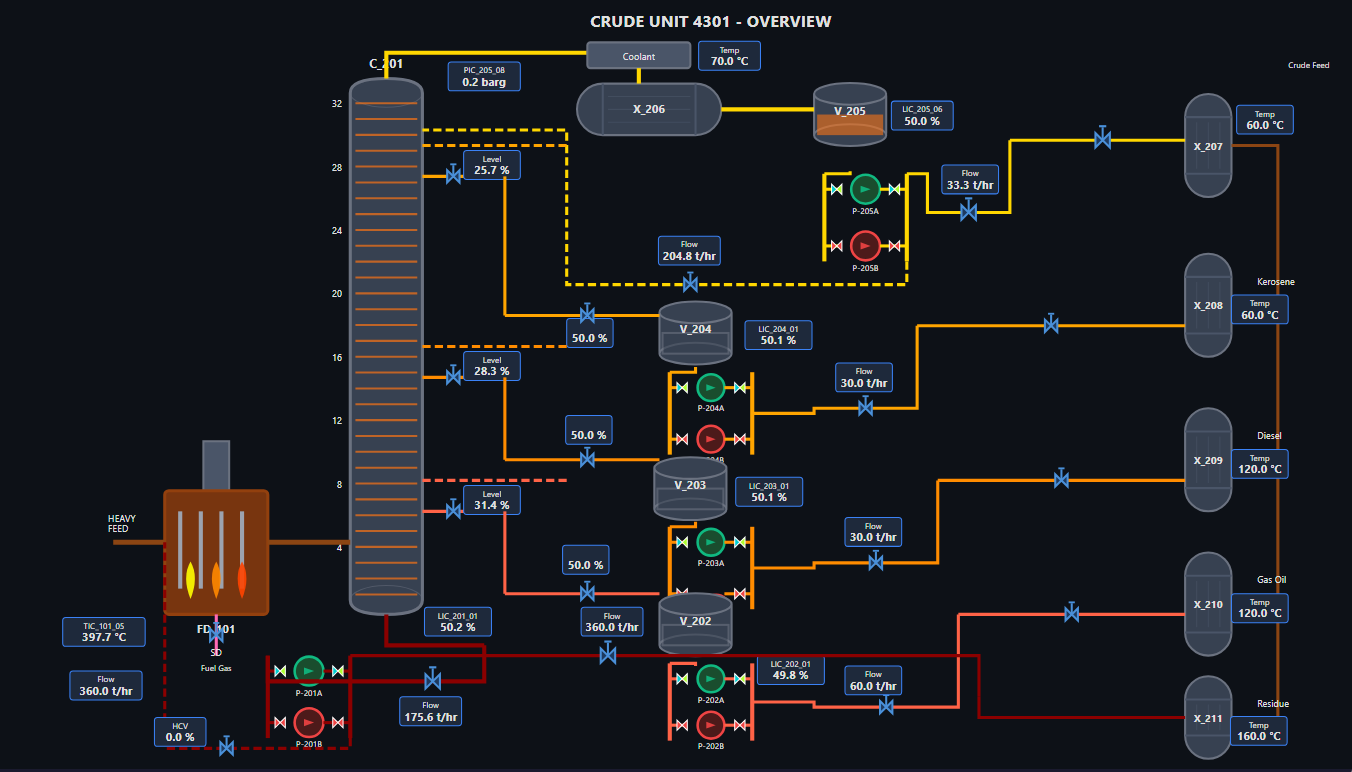

Live Process Graphics

Interactive SVG-based process flow diagrams that update in real time with live plant data, giving operators a clear visual picture of current conditions.

First-Principles Simulation

Rigorous thermodynamic simulation supporting all major process simulators, providing accurate steady-state and dynamic process models with industry-standard property packages.

What-If Scenario Analysis

Test operating changes safely in simulation before applying to the real plant. Evaluate the impact of setpoint changes, feed variations, and equipment outages.

Real-Time Data Integration

Seamless OPC DA connectivity feeds live process data into the digital twin, keeping simulation inputs synchronised with actual plant conditions.

Interactive P&IDs

Navigate your plant through interactive piping and instrumentation diagrams with clickable equipment, live tag values, and drill-down detail views.

Operator Training Mode

Train operators in a risk-free simulated environment that mirrors the real plant. Practice startup, shutdown, and abnormal situation handling without consequences.

From Model to Digital Twin

1. Build Your Digital Plant

Create accurate process models using a first-principles simulation engine and map them to live OPC data sources. MAVEN DTWIN automatically synchronises your digital twin with real plant instrumentation.

- First-principles thermodynamic modelling

- Automatic OPC tag mapping to simulation variables

- Custom SVG process graphics builder

2. Simulate & Analyse

Run what-if scenarios to test operating changes safely in simulation before applying them to the real plant. Evaluate the impact of setpoint changes, feed composition variations, and equipment constraints.

- What-if scenario comparison and ranking

- Safe testing of operating changes offline

- Rigorous thermodynamic predictions

3. Monitor & Optimise

Live dashboards show simulation predictions alongside actual plant values, highlighting gaps and opportunities. Detect anomalies early and identify optimisation potential before issues develop.

- Simulation vs actual value comparison

- Automated gap detection and alerting

- Continuous model calibration and tuning

Under the Hood

| Simulation Engine | Supports all major simulators (Aspen, PRO/II, UniSim, HYSYS, DWSIM) |

| Data Connectivity | OPC DA real-time data integration |

| Process Graphics | SVG interactive graphics with custom shape library |

| Real-Time Updates | WebSocket push for live data streaming |

| Platform | .NET 8.0 on Windows Server 2016+ |

| Shape Library | Custom SVG shapes for process equipment |

| Scenario Management | Multi-scenario comparison and versioning |

| Integration | DCS, SCADA, Historian, OPC servers |