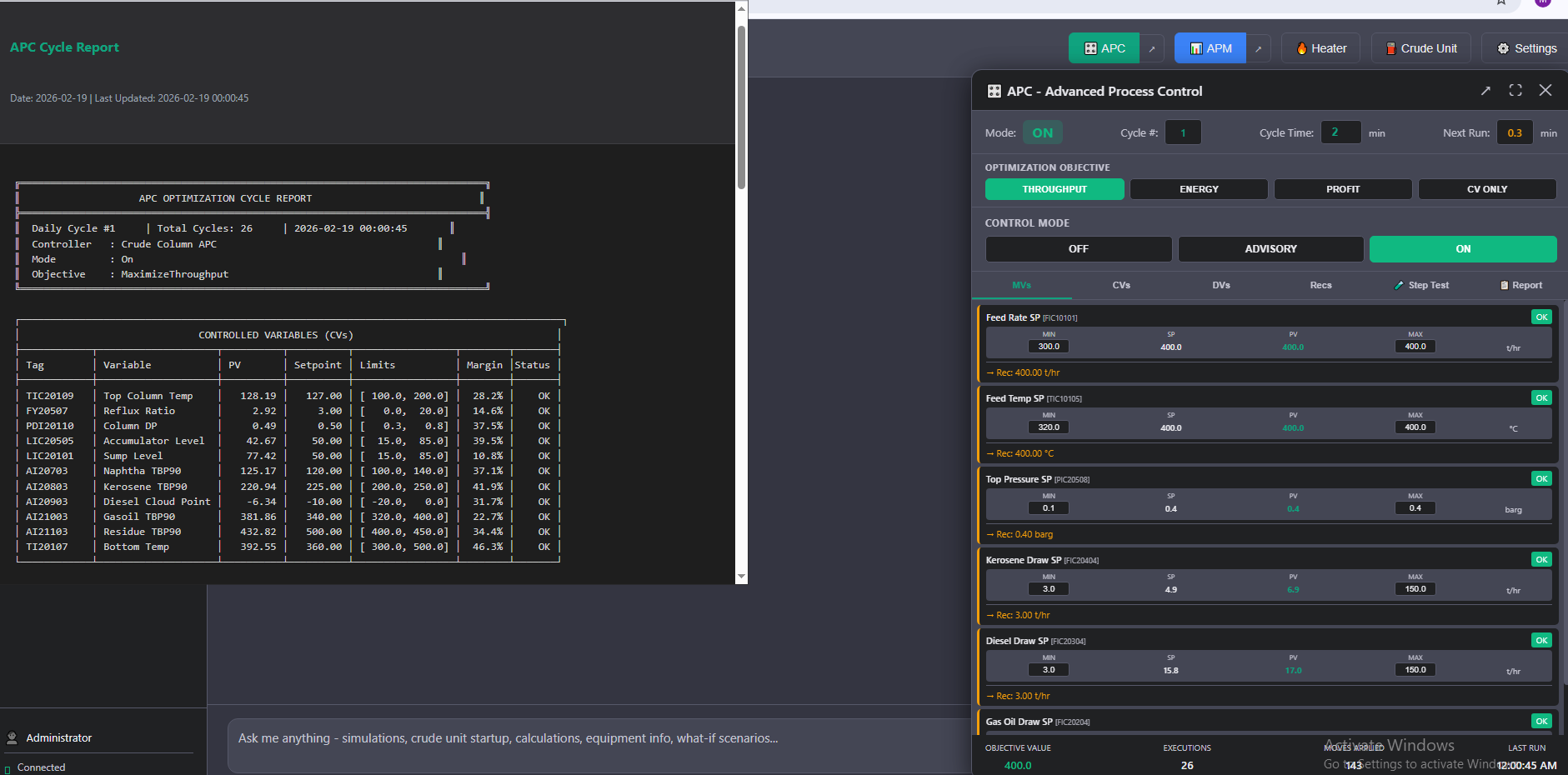

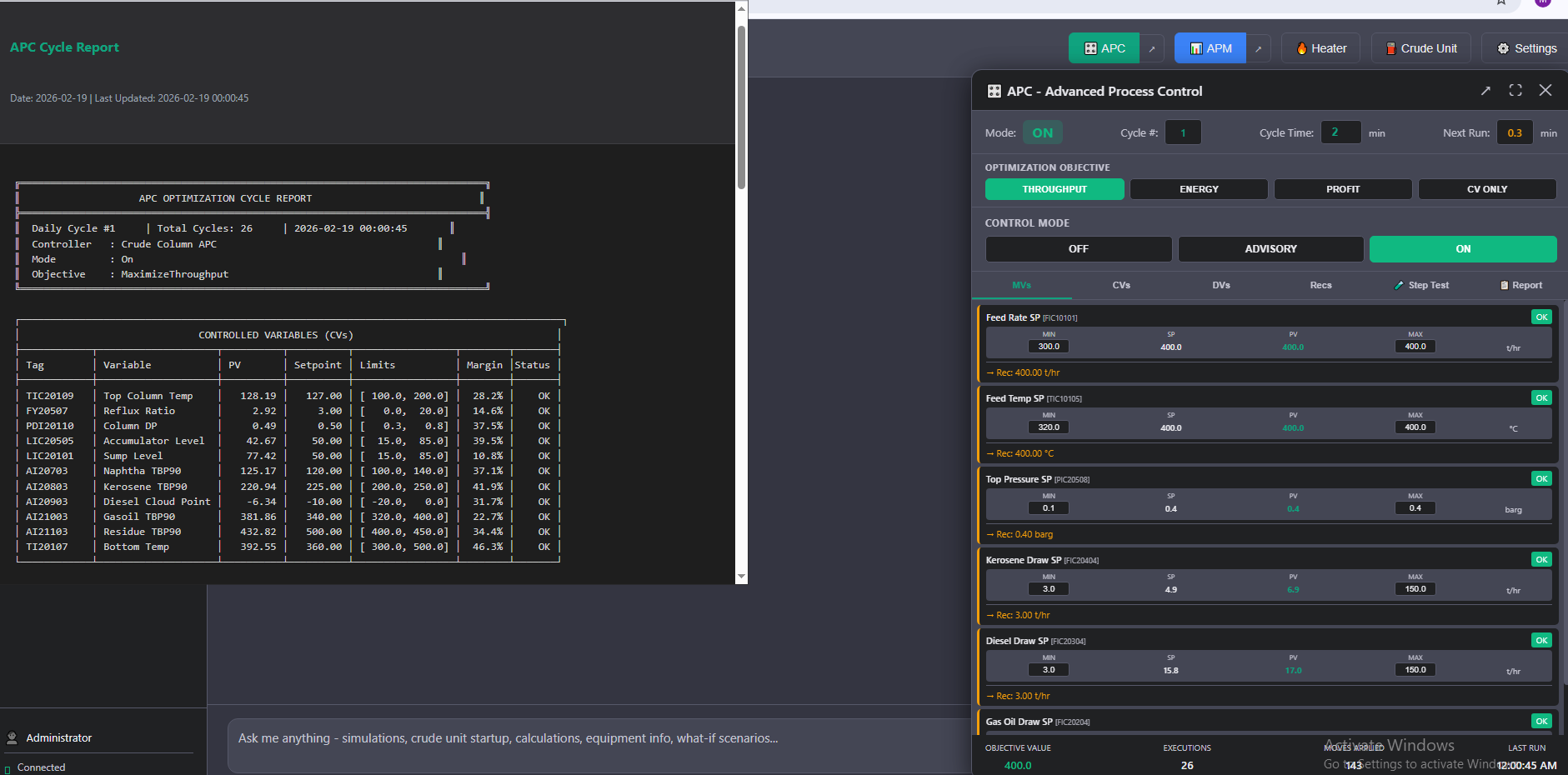

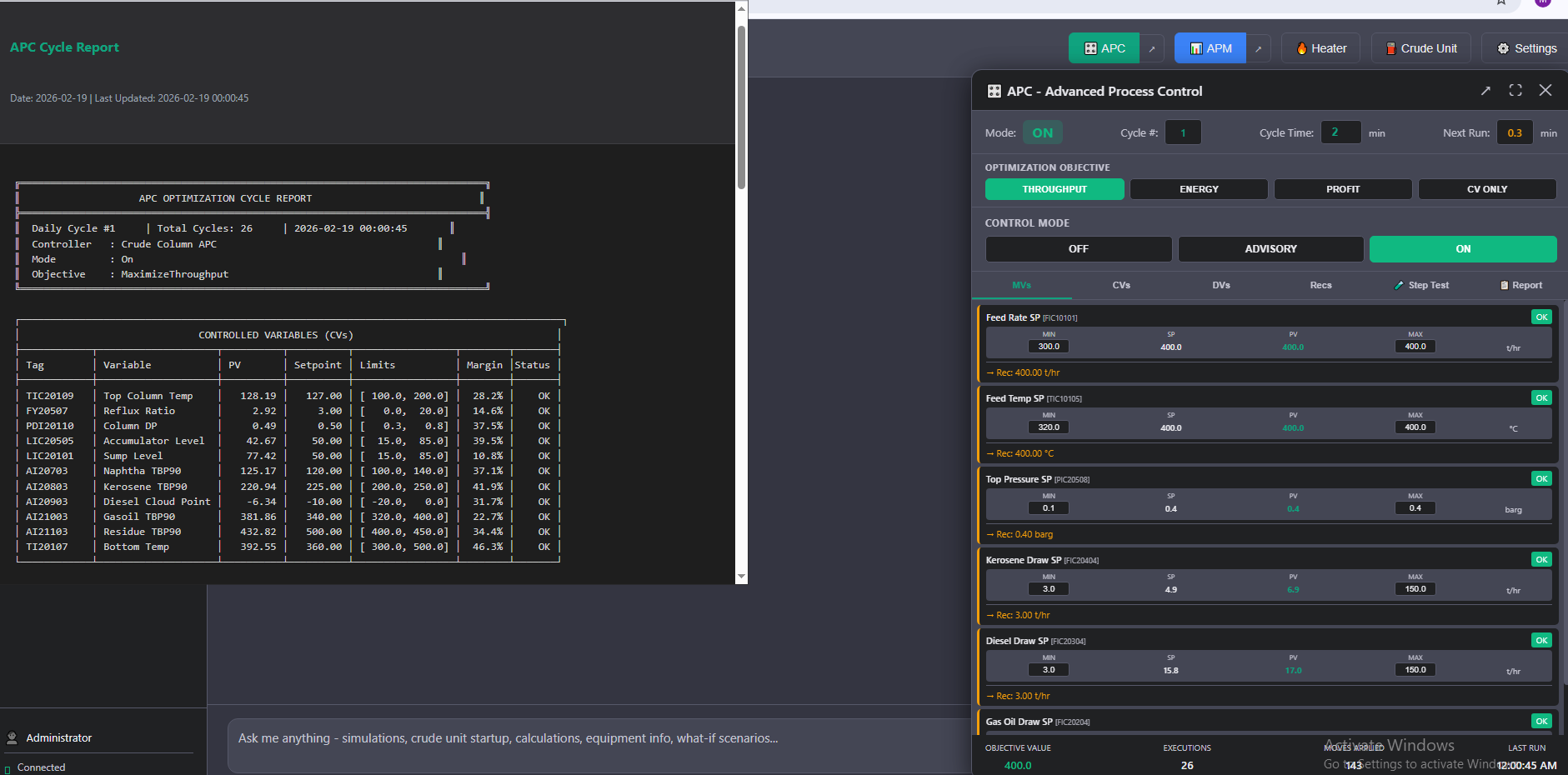

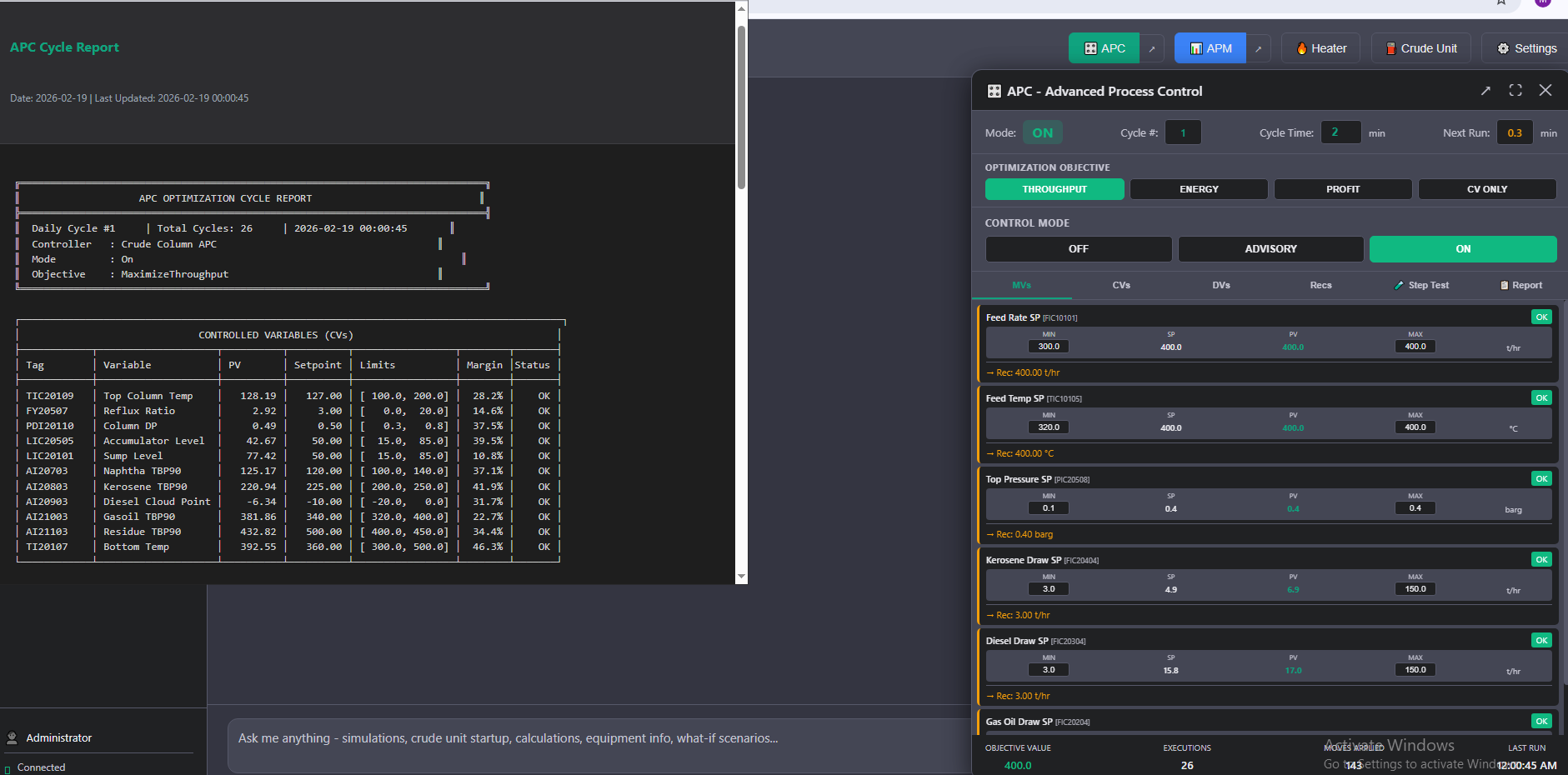

Advanced Process Control

Model Predictive Control that maximises throughput, minimises energy consumption, and maintains product quality — all while respecting operational constraints in real time.

Powerful Control Capabilities

Everything you need for advanced multi-variable process control.

Model Predictive Control

Dynamic MPC engine that predicts process behaviour and optimises control moves across multiple time horizons.

Optimisation Objectives

Configure economic optimisation targets including throughput maximisation, energy minimisation, and quality targets.

MV / CV / DV Management

Comprehensive management of manipulated variables, controlled variables, and disturbance variables with constraint handling.

Step Testing

Automated step-test procedures for model identification with configurable step sizes, durations, and sequencing.

Safety Interlocks

Built-in safety constraint handling with configurable high/low limits, rate-of-change limits, and emergency shutdown integration.

Real-Time Dashboard

Live monitoring of controller performance, model predictions, and constraint status with trend visualisation.

From Model to Control

1. Process Modelling

Build dynamic process models through step testing or historical data analysis. MAVEN APC identifies the relationships between your manipulated and controlled variables automatically.

- Automated step-test sequencing

- Sub-space model identification

- Model validation and diagnostics

2. Controller Configuration

Configure your MPC controller with economic objectives, constraint priorities, and tuning parameters. The intuitive interface makes setup straightforward for control engineers.

- Drag-and-drop variable configuration

- Constraint priority ranking

- Economic objective weighting

3. Real-Time Optimisation

Once deployed, the controller continuously optimises your process, pushing against constraints to maximise economic benefit while maintaining safe, stable operation.

- Steady-state optimisation at every cycle

- Dynamic constraint handling

- Automatic bad-value detection

Under the Hood

| Control Algorithm | Model Predictive Control (MPC) |

| Model Type | Finite Step Response / State Space |

| Execution Rate | Configurable (1s – 60s) |

| Max Variables | 100+ MVs / CVs per controller |

| Communication | OPC DA, OPC UA, Modbus TCP |

| Platform | Windows Server 2016+ |

| Integration | DCS, SCADA, Historian |

| Safety | IEC 62443 compliant architecture |